Iyini i-CNC Machining?

I-CNC machining iyinqubo yokukhiqiza esebenzisa izilawuli zekhompuyutha ukuze isebenzise futhi isebenzise umshini namathuluzi okusika ukuze ilolonge impahla yesitoko—isb, insimbi, ipulasitiki, ukhuni, igwebu, inhlanganisela, njll—ezingxenyeni ngokwezifiso nemiklamo.Ngenkathi inqubo yokwenza imishini ye-CNC inikezela ngamakhono nokusebenza okuhlukahlukene, imigomo eyisisekelo yenqubo ihlala ifana kakhulu kuzo zonke.

Inqubo yemishini ye-CNC ifanele izimboni ezihlukene, ezihlanganisa ezezimoto, i-aerospace, ezokwakha, nezolimo, futhi zikwazi ukukhiqiza uhla lwemikhiqizo, njengamafreyimu e-autombile, izinto zokuhlinza, izinjini zendiza, amagiya nokunye.Inqubo ihlanganisa imisebenzi eminingi yemishini elawulwa ngekhompuyutha ehlukahlukene-okuhlanganisa izinqubo zemishini, zamakhemikhali, zikagesi kanye nezishisayo-ezisusa imethari edingekayo kucezu lokusebenza ukuze kukhiqizwe ingxenye noma umkhiqizo oklanywe ngokwezifiso.

Isebenza Kanjani Imishini Ye-CNC?

Inqubo eyisisekelo yokwenza imishini ye-CNC ihlanganisa izigaba ezilandelayo:

Ukuklama imodeli ye-CAD

Ukuguqula ifayela le-CAD libe uhlelo lwe-CNC

Ilungiselela umshini we-CNC

Ukwenza umsebenzi womshini

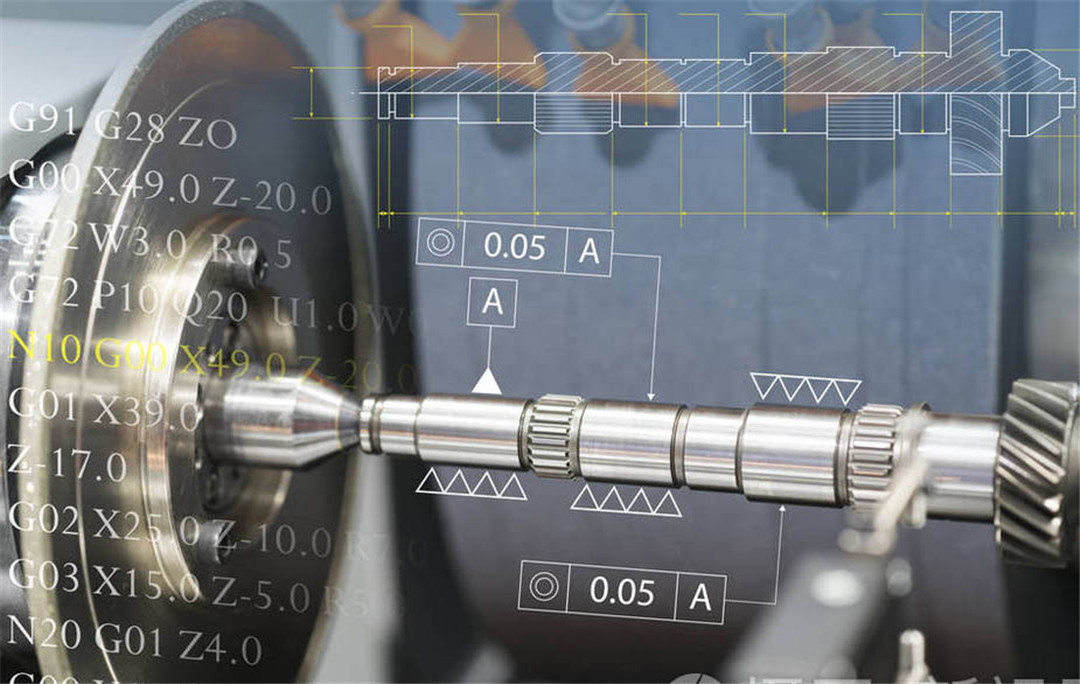

Uma uhlelo lwe-CNC lwenziwa lusebenze, ukusikeka okufunayo kuhlelwa kusofthiwe futhi kubizelwe kumathuluzi ahambisanayo nemishini, eyenza imisebenzi yobukhulu njengoba kucacisiwe, njengerobhothi.Kuhlelo lwe-CNC, umshini wokuphehla ikhodi ngaphakathi ohlelweni lwezinombolo ngokuvamile uzothatha ukuthi izindlela azinasici, ngaphandle kokuthi kungenzeka kube namaphutha, okuba kukhulu noma nini lapho umshini we-CNC uqondiswe ukuthi usike ezindaweni ezingaphezu kweyodwa ngesikhathi esisodwa.Ukubekwa kwethuluzi kusistimu yokulawula izinombolo kuchazwa uchungechunge lokufakwayo olwaziwa ngokuthi uhlelo lwengxenye.

Ngomshini wokulawula izinombolo, izinhlelo zifakwa ngamakhadi e-punch.Ngokuphambene, izinhlelo zemishini ye-CNC zinikezwa amakhompyutha ngamakhibhodi amancane.Uhlelo lwe-CNC lugcinwa kumemori yekhompyutha.Ikhodi ngokwayo ibhaliwe futhi ihlelwe ngabahleli bohlelo.Ngakho-ke, amasistimu e-CNC anikeza amandla okuhlanganisa anwebeka kakhulu.Okuhle kunakho konke, amasistimu e-CNC awamile neze njengoba ukwaziswa okusha kungangezwa ezinhlelweni ezikhona kakade ngekhodi ebuyekeziwe.

Izinhlobo ze-CNC Machining Operations CNC Turning

I-CNC Turning iyinqubo yomshini esebenzisa amathuluzi okusika anephuzu elilodwa ukuze asuse okokusebenza kucezu lokusebenza oluzungezayo.Amandla okusebenza enqubo yokujika ahlanganisa ukubhora, ukubheka, ukugoba, nokusika intambo.Emishinini ye-lathe, izingcezu zisikwa ngendlela eyindilinga ngamathuluzi anenkomba.Ngobuchwepheshe be-CNC, ukusikeka okusetshenziswa ama-lathes kwenziwa ngokunemba kanye nesivinini esikhulu.Izintambo ze-CNC zisetshenziselwa ukukhiqiza imiklamo eyinkimbinkimbi ebingeke yenzeke ezinguqulweni eziqhutshwa mathupha zomshini.Sekukonke, imisebenzi yokulawula ye-CNC-run Mills kanye nezintambo ziyefana.Njengezigayo ze-CNC, amalebula angaqondiswa ngekhodi ye-G noma ikhodi yobunikazi eyingqayizivele.Nokho, iningi CNC lathes aqukethe izimbazo ezimbili - X kanye Z.

I-CNC Milling

I-CNC Milling iyinqubo yokwenza imishini esebenzisa amathuluzi okusika amaphuzu amaningi azungezisayo ukuze asuse impahla kucezu lokusebenza.Izigayo ze-CNC ziyakwazi ukusebenza ezinhlelweni ezihlanganisa izinombolo nezinhlamvu eziqondisa izingcezu ezihlanganisa amabanga ahlukahlukene.Uhlelo olusetshenziswa emshinini wokugaya lungase lusekelwe ku-Gode noma ithimba elithile elihlukile elithuthukisiwe, i-Basic m-cos ihlanganisa isistimu yama-eksisi amathathu (X, Y kanye no-Z), nakuba izigayo eziningi ezintsha zingamukela izimbazo ezintathu ezengeziwe.Amandla okusebenza enqubo yokugaya ahlanganisa ukusika ubuso okungashoni, indawo eyisicaba kanye nama-cavitite aphansi-phansi endaweni yokusebenza-kanye nezimbotshana ezijulile zokusika, njengezikhala nemicu, zibe ucezu lokusebenza.

5 Umshini we-axis

Imishini ye-axis engu-3, 4, noma engu-5 ichazwa ngokuhlobene nenani lezikhombisi-ndlela lapho ithuluzi lokusika lingahamba khona, lokhu kuphinde kunqume ukukwazi komshini we-CNC ukuhambisa ucezu lokusebenza nethuluzi.Izikhungo zemishini ye-3-eksisi zingakwazi ukuhambisa ingxenye ku-X kanye nezikhombisi-ndlela zika-Y futhi ithuluzi lehla liye phezulu naphansi eduze kwe-axis engu-Z, kuyilapho esikhungweni somshini we-axis engu-5, ithuluzi lingakwazi ukuhamba linqamule izimbazo ezingumugqa zika-X, Y kanye no-Z kanye izungeza kuma-ax e-A no-B, okwenza umsiki akwazi ukusondela endaweni yokusebenza kunoma iyiphi indlela nanoma iyiphi i-engeli.5 i-axis machining ihlukile kune-5-side machining.Ngakho-ke, izinsiza zemishini ye-axis ye-CNC ezi-5 zivumela amathuba e-infinte ezingxenye ezifakwe ngomshini.Umshini we-hook surface machining, umshini wokwakheka okungajwayelekile, umshini ongenalutho, ukubhoboza, ukusika i-oblique, nezinye izindlela ezikhethekile zingaba nensizakalo yemishini ye-CNC ye-axis engu-5.

I-Swiss Type Machining

Ukunyathelisa kohlobo lwase-Swiss kubizelwa ukwenziwa ngomshini nge-Swiss type lathe noma i-lathe yase-Swiss automatic, iwukukhiqiza okunembayo kwesimanje okungakhiqiza izingxenye ezincane kakhulu ngokushesha nangokunembile.

Umshini wase-Swiss usebenza ngokuphakela isitokwe sebha ngokusebenzisa i-guiding bushing, esekela ngokuqinile impahla njengoba ingena endaweni yamathuluzi yomshini.

Uma kuqhathaniswa namalebula e-traidtional automatic lathes ohlobo lwe-Swiss ayakwazi ngokukhethekile ukukhiqiza izingxenye ezincane kakhulu, ezinembayo ngesivinini esisheshayo.Inhlanganisela yokunemba okuphezulu kanye nevolumu yokukhiqiza ephezulu yenza imishini yaseSwitzerland ibe ucezu olubalulekile lwemishini ezitolo okufanele zikhiqize umthamo omkhulu wezingxenye ezincane neziyinkimbinkimbi ezinomkhawulo omncane wephutha.

Izinto ezisetshenziswa ku-CNC Machining Application

Yize kunezinhlobonhlobo zezinto ongazisebenzisa emshinini we-CNC, izinto ezisetshenziswa kakhulu ezisetshenziswa yilezi:

Ama-aluminium Alloys

● Al 6061-T6

● I-Al6063-T6

● I-Al7075-T6

● I-Al5052

● Al2024

Ama-alloys ensimbi engagqwali:

● Insimbi engagqwali 303/304

● Insimbi engagqwali 316/316L

● Insimbi engagqwali 420

● Insimbi engagqwali 410

● Insimbi engagqwali 416

● Insimbi engagqwali 17-4H

● Insimbi engagqwali 18-8

Ipulasitiki:

● I-POM (Delrin),ABS (Acrylonitrile Butadiene Styrene)

● I-HDPE, Inayiloni(PA),PLA,PC (Polycarbonate)

● I-PEEK (I-Polyether Ether Ketone)

● PMMA (Polymethyl Methacrylate noma Acrylic)

● PP (I-Polypropylene)

● PTFE (Polytetrafluoroethylene)

Ama-alloys e-Copper & Brass:

● I-Copper 260

● I-Copper 360

● H90, H80, H68, H62

I-Carbon steel Alloys:

● Insimbi 1018, 1024, 1215

● Insimbi 4140, 4130

● Insimbi A36...

I-Titanium Alloys:

● I-Titanium (Ibanga lesi-2)

● I-Titanium (Ibanga lesi-5)

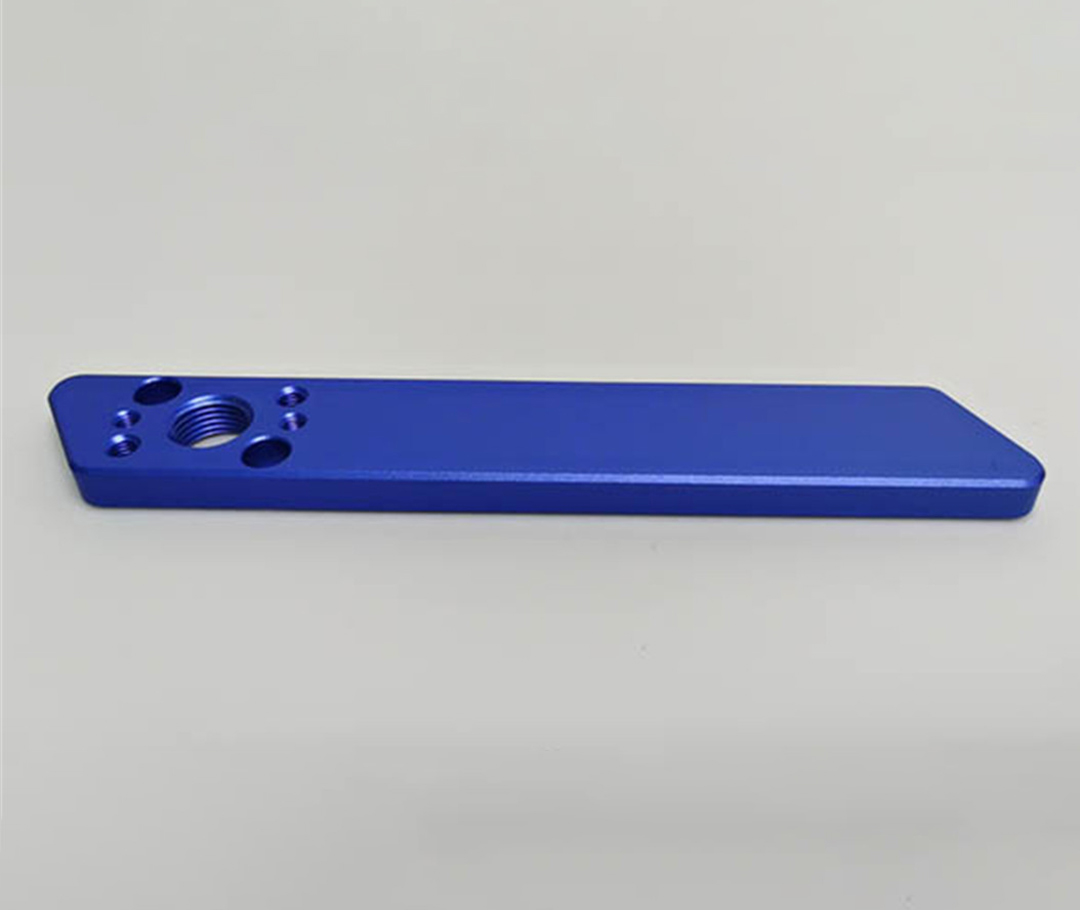

Izinketho ze-CNC zokuqeda kanye ne-Post-processing

Ukuqedwa kobuso kuyisinyathelo sokugcina somshini we-CNC.Ukuqeda kungasetshenziswa ukususa amaphutha obuhle, ukuthuthukisa ukubukeka komkhiqizo, ukunikeza amandla engeziwe nokumelana, ukulungisa ukuqhutshwa kukagesi, nokunye okuningi.

● Njengomshini

● I-Anodizing (Uhlobo II Nohlobo III)

● Ukugcoba ngempuphu

● I-Electroplating

● Ukuqhunyiswa kobuhlalu

● Ukuwa

● Ukuthakasela

● Ifilimu Yekhemikhali(I-Chromate Conversion Coating)

Buka ezinye Izibonelo Zezingxenye Zethu Zemishini Ye-CNC

Izinguquko Zoku-oda Izingxenye Zomshini Ze-CNC kusuka ku-Star Machining

Ukushintsha Okusheshayo:Impendulo esheshayo ye-RFQ phakathi kwamahora angama-24.Isebenzisa imishini yakamuva ye-CNC, i-Star Machining ikhiqiza izingxenye ezinembe kakhulu, eziphenduka ngokushesha ngokushesha njengezinsuku eziyi-10.

Ukunemba:I-Star Machining inikezela ngezinketho ezahlukahlukene zokubekezelela ngokuya ngezinga le-ISO 2768 futhi eliqine kakhulu ngokwesicelo sakho.

Ukukhetha okubalulekile:Khetha ezintweni ezingaphezu kuka-30 zensimbi nepulasitiki njengoba udinga.

Ukuqeda Ngokwezifiso:Khetha ezinhlotsheni ezihlukene zika-o ezingxenyeni zensimbi eziqinile nepulasitiki, ezakhelwe ukucacisa okunembayo kwedizayini.

Isipiliyoni:Onjiniyela bethu abacebile abanolwazi bazokunikeza impendulo esheshayo ye-DFM.I-Star Machining ineminyaka engaphezu kwe-15 yokuphatha ukukhiqiza.Kunezinkulungwane zezinkampani namaphrojekthi esiwasebenzele ezimbonini ezahlukahlukene, emazweni angaphezu kwama-50 esiwathumele.

Ikhwalithi yokulawula:Umnyango wethu we-QA wenza isiqiniseko esiqinile sekhwalithi.Ukusuka kokubalulekile kuye ekuthunyelweni komkhiqizo wokugcina sihlola ngokuqinile ngezinga lamazwe ngamazwe.Ezinye izingxenye sizenza ukuhlolwa okuphelele njengesicelo samakhasimende.

Ukulethwa Okusheshayo:Ngaphandle kwenkampani yenethiwekhi eqokiwe, sinaye i-ejenti yethu ye-DHL/UPS kanye nomdluliseli ongathumela izingxenye zakho ngokudiliva okusheshayo namanani anengqondo.