Esikwenzayo

I-Star Machining Technology ingumkhiqizi wesikhunta ochwepheshe, osebenza ngokukhethekile ekubumbeni okukhulu nokuyinkimbinkimbi, sihlinzeka ngesixazululo sesikhunta esisodwa-stop, esihlanganisa ukwakheka komshini wengxenye yesikhunta, ukwakheka kwesikhunta, ukwakhiwa kwesikhunta, ukukhiqizwa kwepulasitiki noma ingxenye yokuphonsa kanye nezinsizakalo zokucutshungulwa kwesibili.

Kwa-Star Machining Technology, sinolwazi olujulile lokuklama nokucacisa ukwakhiwa kwesikhunta se-aluminium die casting kanye nokubunjwa komjovo.Siqala ukwenza isikhunta kusenesikhathi ngokusebenzisana nawe ukuze sinqume amandla okwenza umklamo.Sizosiza futhi ukusungula indlela yokusebenza yengxenye eqediwe.Lokhu kubandakanyeka kwangaphambili ekwakhiweni kwesikhunta se-die casting kanye nenqubo yokuhlaziya kusiza ukuqinisekisa ikhwalithi yomkhiqizo.Singakwazi ukukhiqiza imiklamo yamathuluzi enemininingwane, ukuphrinta kwengxenye kanye nokucaciswa kwesibonelo sakho, noma amafayela akho e-2D noma e-3D CAD.Abenzi bethu besikhunta abangochwepheshe bakunikeza okungcono kakhulu kwemihlaba yomibili: inqubo ephambili nemishini ezandleni zezingcweti ezinekhono nezinolwazi.Idizayini yethu eqondile yokubumba kanye namakhono okwakha anemba ahumushela ohlelweni lokukhiqiza olukhiqiza izingxenye zekhwalithi evelele.Lapho uthuma i-Star Machining Technology ukuthi yakhe isikhunta sakho, uqinisekiswa ngezingxenye ezinokusebenza okungaguquki kanye nembuyiselo ephezulu ekutshalweni kwakho kwamathuluzi.

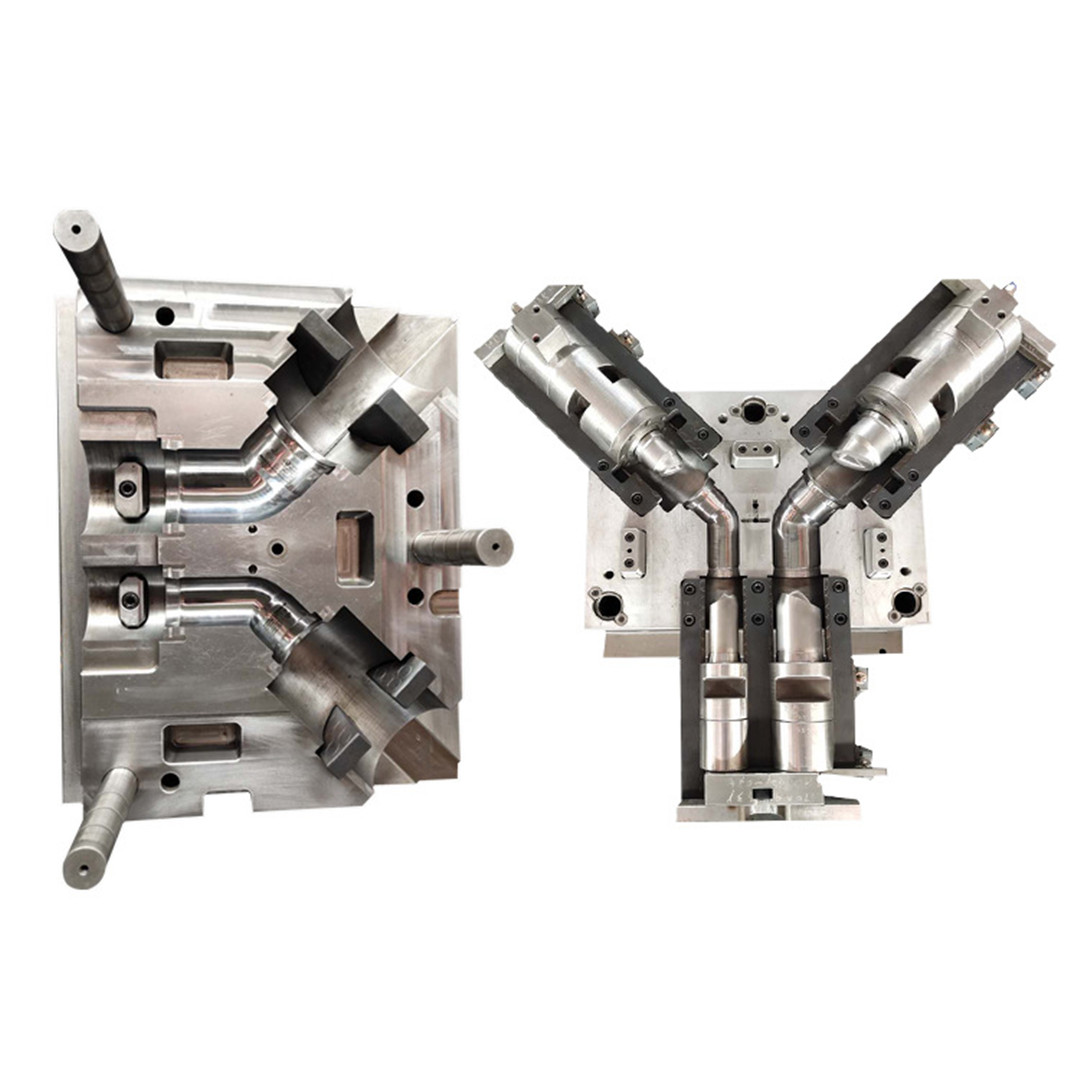

Futhi siyaqonda ukuthi izingxenye ezifakwe kakhulu, ezibekezelelwa kakhulu, ezinezikhathi zokuhola ezinolaka, zidinga amathuluzi ekhwalithi ephezulu—kusukela emkhiqizweni wokuqala phakathi nokuphila komkhiqizo wakho.Kungakhathaliseki ukuthi sakha isikhunta sesibonelo esisodwa noma i-multi-cavity, isikhunta sokukhiqiza uhlaka olugcwele, ithuluzi elikhethekile liphakathi kwe-Star Machining Technology's die casting molding kanye nomsebenzi wokubumba umjovo.

Amakhono Ethu Onjiniyela Afaka:

Ingxenye yokuklama:Sakha imikhiqizo eyenza amathuluzi angabizi kakhulu

Ukuhlaziywa kokugeleza:Senza ukuhlaziywa kwe-plastic melt flow analysis nge-Moldex3D

I-Mold Design:Yonke imiklamo idalwe kusetshenziswa i-Creo Parametric

Ucwaningo Namazinga:Sigcina umtapo wezincwadi wamazinga ekhasimende ngalinye

Ukubikwa kwenqubekelaphambili:Amashadi nezibuyekezo zenqubekelaphambili ezijwayelekile zenziwe zatholakala

Ukudluliswa Kwedatha Ye-elekthronikhi:I-FTP kanye nezinanyathiselwa ze-imeyili ziyatholakala

Gcina futhi ubuyekeze i-CAD

Izinhlobo Zesikhunta Esikunikezayo

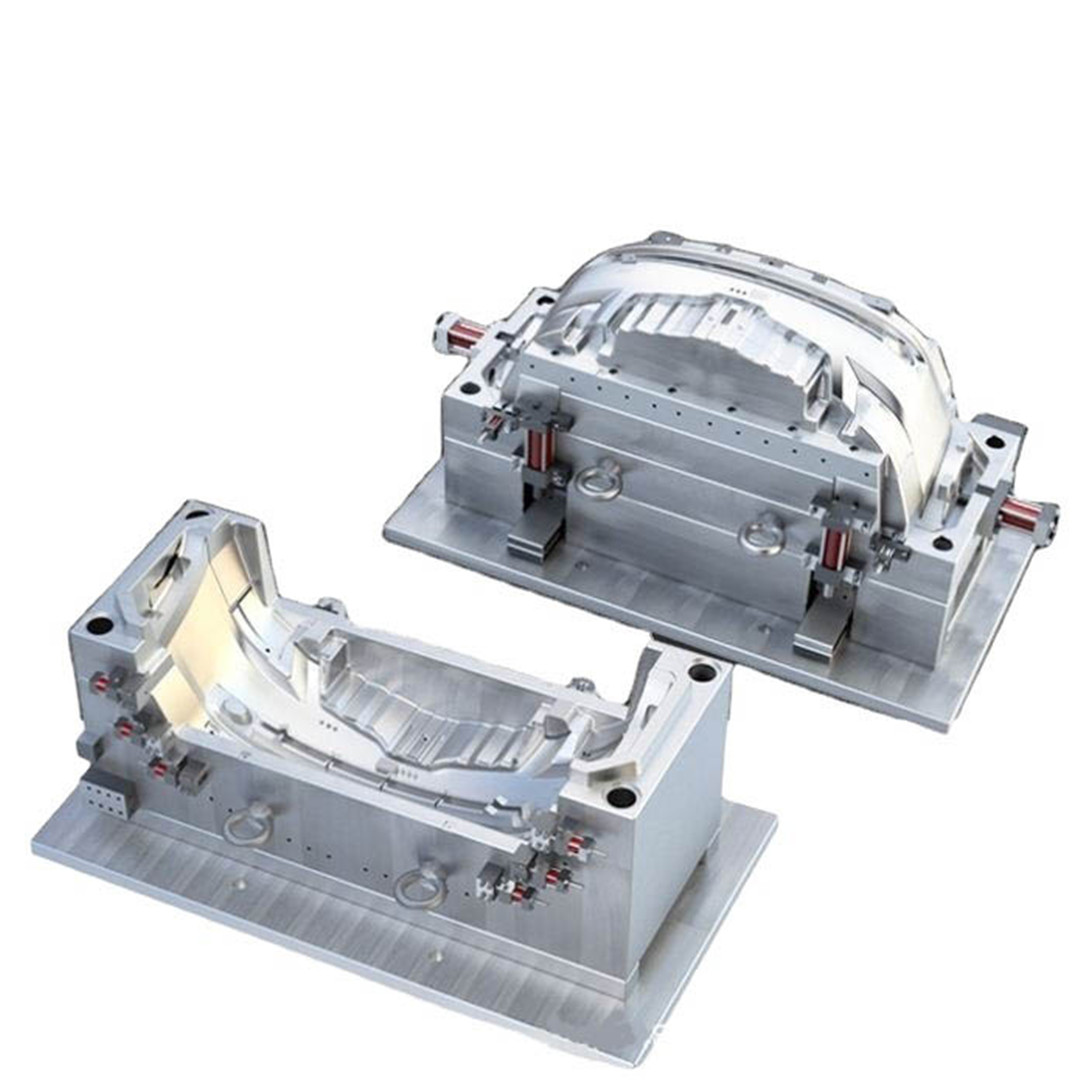

Die Casting Mold

Ngokungafani nochwepheshe abaningi be-prototyping, singahlinzeka ngokubumba kwensimbi (kanye nesevisi yokusakaza yevolumu ephansi ngozakwethu).Lezi zibunjwa - ngokuvamile ezenziwe ngensimbi eqinile - zingasetshenziselwa ukwenza izingxenye ze-aluminium, zinc, i-magnesium nezinye izinsimbi ezingenayo insimbi.

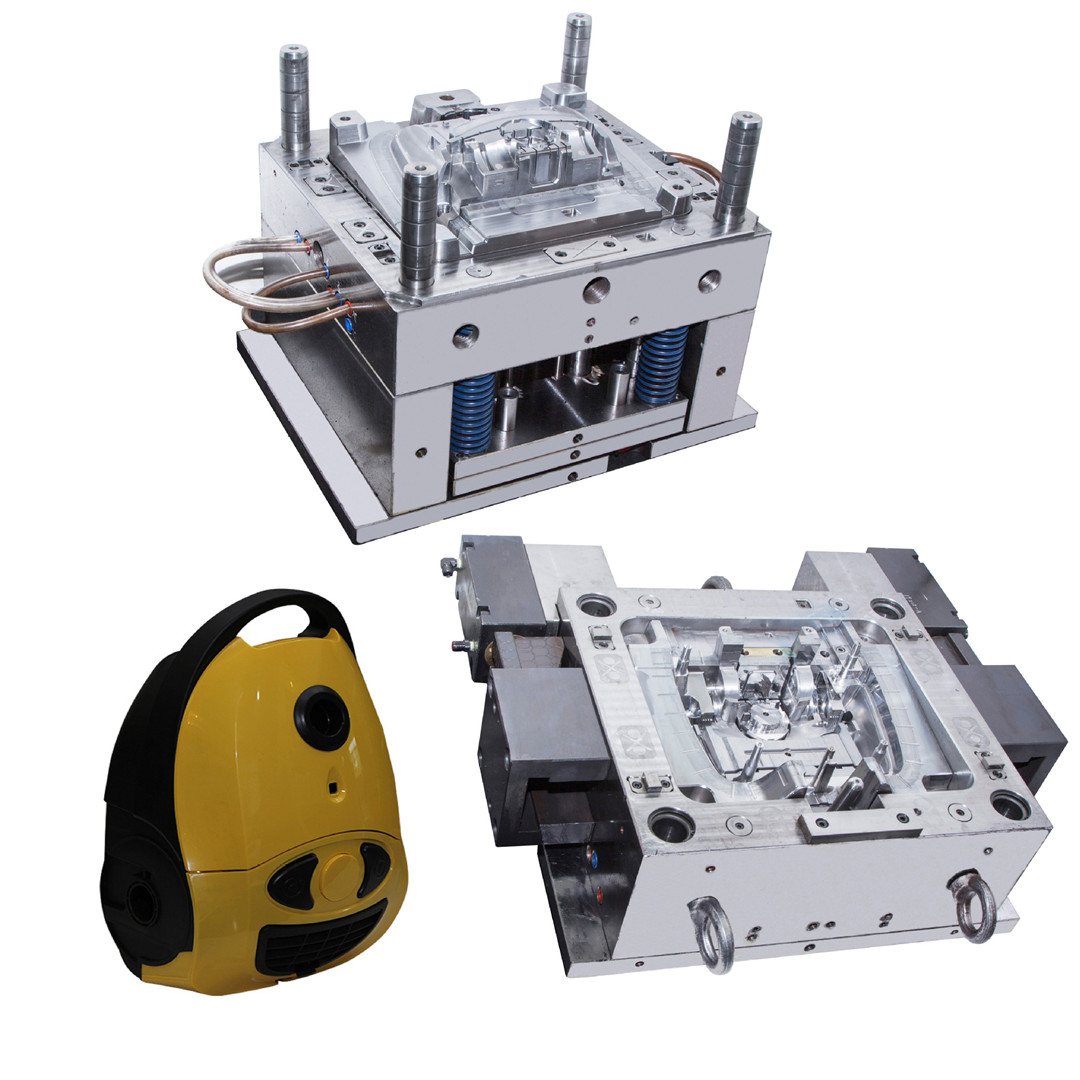

Isikhunta sePlastiki sokujova

Izibunjwa zomjovo wepulasitiki ziyi-aluminium noma isikhunta sensimbi esisetshenziselwa ukwenza izingxenye ezivela enhlobonhlobo yamapulasitiki, okuhlanganisa inayiloni, ama-acrylics, ama-elastomers nezinto eziqinisiwe njenge-polyamide egcwele ingilazi.Izibunjwa zepulasitiki zangokwezifiso zingahlala phakathi kwamashothi ayi-10,000 kanye ne-1,000,000.

Izinqubo Zokwenza Isikhunta

Ukwenza isikhunta kuyinqubo eyinkimbinkimbi edinga izinga eliphezulu lekhono nolwazi.Nakuba icala ngalinye lihlukile, ukuhleleka okujwayelekile kweqoqo lezibunjwa kungase kuhambe kanje:

1. I-DFM

Ngokushesha nje lapho ikhasimende liqinisekisa ukuhleleka kwesikhunta, sizoqala ukwenza ukuhlaziywa kokuqala kwezingxenye ukuze sithole umbono wengxenye yomugqa, izikhundla zesango, njll.

2. Ukwakhiwa kwesikhunta nokuhlaziywa kokugeleza kwesikhunta

Isinyathelo sesibili sihilela ukusetshenziswa kwesofthiwe yokubikezela imodeli esivumela ukuthi sibone ukuthi impahla encibilikisiwe izoziphatha kanjani lapho ingena esikhunjeni, okuvumela ukuthuthukiswa okuqhubekayo kumklamo.

3. CNC machining kanye EDM

Senza isikhunta sokuqala sisebenzisa imishini yokwenza imishini yekhwalithi ephezulu, ngepulasitiki, insimbi, i-aluminium, njll. ekhethwe ikhasimende.

4. T1 isampula

Ngesikhunta esisanda kwenziwa, senza isampula ye-T1 ukuze sibe nombono ocacile wokuthi izingxenye ezibunjiwe zokugcina zekhasimende zizoba kanjani.

5. Ukuthuthukiswa uma kunesidingo

Ngokusekelwe ekuhlaziyeni kwethu isampula ye-T1, sibuyekeza ukwakheka kwesikhunta futhi senze noma yiziphi izinguquko ezidingekayo.

6. Qala ukukhiqiza nokuthumela

Senza isikhunta ngokuhambisana nemininingwane yokugcina ngaphambi kokuyithumela ekhasimendeni.